Garage Door Parts That Require Regular Lubrication

Garage doors add a valuable design element to homes. All garage owners want the door to function as quickly, quietly, and smoothly as possible. Several distinct components work and move in coordination to allow a garage door to operate effectively. The movement creates friction and leads to wear and tear of the parts over time. Regular upkeep ensures that the garage door remains in top shape and prevents unnecessary spending on repairs or replacements.

Lubricating the moving components is one of the most critical steps in garage door maintenance that minimizes friction and restores proper functionality. It also reduces the squeaky and grinding noises, extends the system's life, and keeps it running seamlessly.

Let's look at the various garage door parts that need regular lubrication to limit wear and tear:

Springs and bearing plates

It is vital to lubricate the torsion springs, as the garage door heavily relies on them to open and close. With constant use, the lubricant wears off, leading to loud and annoying noises. Cover the springs and bearing plates with grease, but avoid soaking them with it.

Hinges

Hinges connect the door sections. It is first essential to determine whether the garage door uses plastic or metal hinges. Do not lubricate the plastic hinges, as it contributes to their premature degradation. Clean them with a cloth or duster to get rid of any dirt. Lubricate only the metal hinges at their pivot points.

Tracks

Tracks are a vital part of the garage door mechanism that requires lubrication annually. They attract dirt, dust, cobwebs, and other debris. Therefore, it is essential to clean them regularly to remove build-up; wipe them down with a sponge to keep the surface spotless.

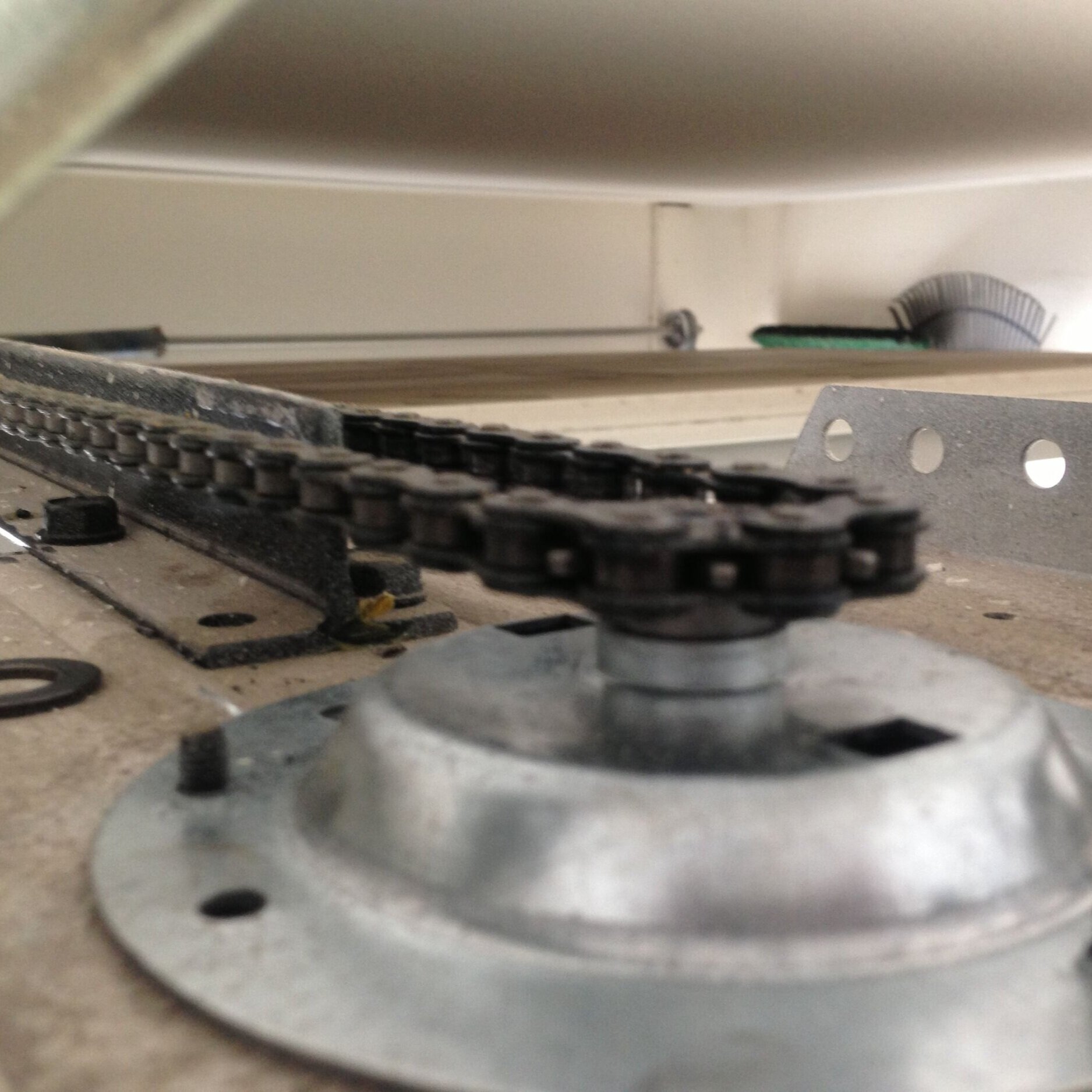

Rollers

Rollers are responsible for running the garage door smoothly up and down the tracks. For metal wheels, thoroughly apply the lubricant directly and wipe away excess grease to prevent it from dripping on the garage floor. For a garage door with nylon wheels, only lubricate the bearings and avoid getting any on the nylon.

Locking mechanism

Locks do not require frequent lubrication when compared with other parts. A lock should only be lubricated if the key sticks or if it's difficult to open or close it. Spray it with a lubricant, and ensure it gets into the moving parts.

Lubricate the rollers, springs, and hinges once every three to six months to minimize noise and other issues. Post lubrication, operate the garage door a few times to ensure that the lubricant is evenly distributed.

Choose the right lubricant

There are several garage door lubricants available, and choosing the right one defines the process's effectiveness. Experts suggest using a white lithium grease or silicone spray to lubricate the moving garage door parts. Aerosols also work well, as they don't attract dust and are easy to inject into smaller components. Avoid using WD-40, the popular oil-based spray useful in making metal parts work better. Its degreasing properties are not suitable for the garage door.

Lubricating a garage door is a DIY task that homeowners can routinely perform using a good quality lubricant. Hire professionals for other garage door repair and replacement services. Annual inspection and maintenance by experts ensure that potential issues get fixed before they create serious trouble.

Quality Overhead Door is a family-owned and operated business offering honest and reliable garage door openers, garage door cable replacement, and garage door maintenance services in Phoenix, AZ. We offer upfront prices and are committed to delivering exceptional services. Contact us and we will get back to you quickly.